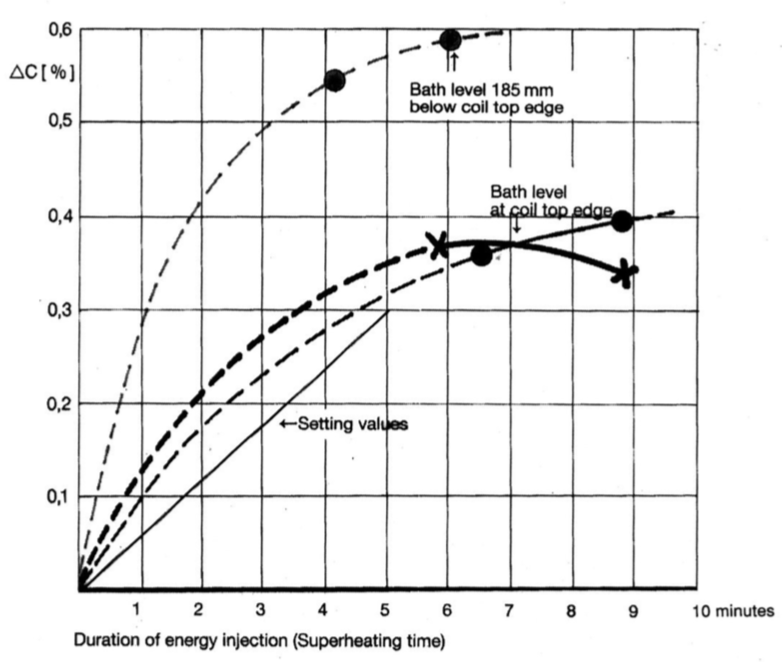

Carbonisation is essential in the production of cast iron from steel scrap and carbon, since the exact carbon content is very rarely achieved with the metallurgical sample. As a rule, the carbon content must be increased by up to 0.3%.

The induction crucible furnace is very well suited for the carbonisation process. The bath movement, agitating effect and the simultaneous temperature increase produce the optimum results, provided that the following conditions are also observed. For 0.3% carbonisation, these are 5 minutes agitation time, a temperature increase of 100 K and a bath filling level above the active induction coil of approx. 25% of the coil height for mains frequency (50/60 Hz), and about 5% of the coil height for medium frequency (500 Hz) with the same specific performance. The specific performance for equal bath movement is 300 kW/t for mains frequency, 545 kW/t at 250 Hz and 750 kW/t at 500 Hz.

If in certain cases carbonisation by approx. 0.5% is required, an agitation time of approx. 7 minutes must be provided, in addition to increasing the

temperature differential from 100 K to 130 K, in order to achieve reliable dissolution of the carbon in the melt.

For the 3 frequencies specified above, the following furnace sizes and performances can be regarded as ideal:

| NF-50/60Hz | 12.5t – 3,000kW | 9 minutes | for 100 K – 25% over-filling |

| MF-250Hz | 5.5t-3,000kW | 4 minutes | for 100 K – 25% over-filling |

| with 2,400kW | 5 minutes | for 100 K – 20% over-filling | |

| with 3,000kW | 5 minutes | for 125 K – 25% over-filling | |

| MF-500Hz | 4.0t-3,000kW | 3 minutes | for 100 K – 25% over-filling |

| with 1,800kW | 5 minutes | for 100 K – 15% over-filling | |

| with 3,000kW | 5 minutes | for 166 K – 25% over-filling |

From these figures, it can be seen that a mains frequency furnace can be overfilled by approx. 300 mm, a 250 Hz furnace by approx. 220 mm and a 500 Hz furnace with suitable performance by approx. 150 mm.

If a significantly higher specific performance is installed, due to the melting performance per hour required for operation, the metallurgical melting control must be properly set, and when reaching the upper edge of the coil, the required quantity of carbon for the final filling level must be added.

For example, a 5.5 t furnace operating at 4,800 kW has a superheating capacity of 40 K/minute, and thus an agitating time of approx. 2.5 minutes for 100 K. In order to maintain the agitating time of 5 minutes, the temperature difference would have to be 200 K. This value is not realistic in practice. This furnace should be operated at approx. 3,000 kW for about 5 minutes with a temperature difference of 125 K.

movement force, which in an induction crucible furnace acts vertically to the wall, and thus pushes the melt away from the crucible wall. The melt can only compensate for this force in an upward direction, and this creates the bath cone, which is higher or lower depending on the performance and frequency.